SPOILER ALERT!

Making Use Of Building Metal Panel To Enhance The Outside Of A Building

Content by-Barbour Wolfe

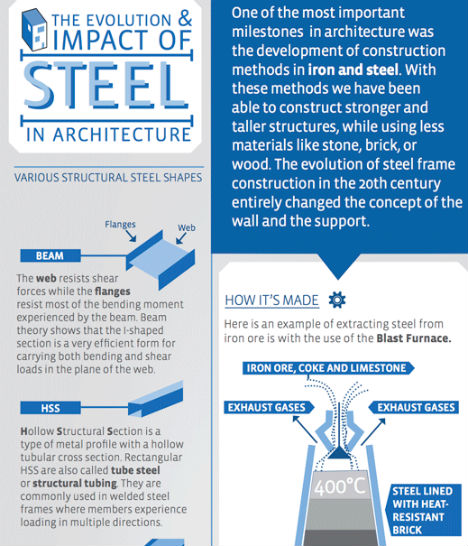

Whether you're dealing with a premium business task or you're on a limited budget plan, building metal panel can use a wealth of layout choices to satisfy your building's needs.

Unlike various other outside wall cladding systems, building steel panels offer an endless number of style options and are usually less expensive to set up than traditional house siding. They are additionally extremely reduced upkeep.

Metal panels can be found in a variety of styles and also surfaces, providing engineers with unlimited opportunities for creating special, custom-made designs. They're likewise durable, light-weight and also reasonably simple to mount.

When choosing a metal wall surface panel system, ensure it has actually passed fire as well as wind examinations. https://www.carsguide.com.au/car-news/why-2022-toyota-landcruiser-300-series-buyers-might-pay-higher-insurance-premiums-to-cover will make sure that the system is correctly shielded as well as can hold up against high wind loads, which can create damage to your structure.

A fantastic way to attain this is by selecting an insulated metal panel (IMP) that has actually undergone NFPA 285, a fire examination from the National Fire Protection Association. This will assist to guarantee your building is secured from fire and also will certainly last longer than a common panel system.

IMPs are a superb option for lots of roof covering and also wall applications, but it's important to make sure that the panels are set up appropriately. Taking a couple of minutes prior to the beginning of a project to assess mounting alignment as well as mount shims will certainly assist stay clear of expensive mistakes.

An architectural metal panel system is an effective means to enhance the outside of a building. These panels are available in a wide range of colors, sizes and also coatings to match any type of layout theme or budget.

They are additionally extremely resilient and also reduced upkeep, unlike timber or concrete. While various other products can crack, chip or discolor with time, steel remains strong and also gorgeous.

To maintain metal wall surface cladding looking its finest, see to it to clean it with a soft cloth as well as an option of water as well as neutral cleaning agent. Never ever use a severe industrial detergent or sharp cleansing devices, as these can harm the panels' surface area.

Furthermore, make certain to get rid of any type of particles or standing water from the base of your metal wall surface cladding. This will aid protect against rot and lengthen the life of your cladding.

The power effectiveness of structures is a crucial factor in reducing emissions that contribute to climate change. To minimize power loss as well as improve a structure's overall power performance, designers as well as specialists are turning to airtight insulated steel panels with optimum thermal resistance.

These panels supply a complete vapor as well as water barrier that inhibits power loss, which can help a building satisfy progressively rigorous power code requirements. Their high R-values allow building groups to satisfy or exceed minimal power efficiency requirements as well as get LEED score points.

Metl-Span's CF Architectural, Mesa, 7.2 Insul-Rib as well as ThermalSafe panels provide extraordinary energy performance in business applications. Along with their remarkable thermal effectiveness, these panels offer a top quality appearance that is cost-competitive with other protected wall surface systems.

Whether you're utilizing it for exterior wall surface cladding or trim, or to develop a roofing system deck, architectural metal panel is an incredibly long lasting option. It can hold up against impacts, water damages, and even deterioration.

Resilience is essential when it involves building outsides, because it can avoid structural damage from things like wind, rainfall, as well as hail storm. It can likewise assist secure a building's interior from leaks.

In order to have a sturdy product, it should be coated with a reliable safety layer that can withstand severe weather. A lot of these finishings are available for aluminum, stainless steel as well as copper panels.

Along with durability, steel panel systems need to be crafted for gravity, seismic and wind loading. They additionally require to be attached to a structural framework that can handle flexing or motion due to thermal growth as well as differential motions between panels.

Whether you're dealing with a premium business task or you're on a limited budget plan, building metal panel can use a wealth of layout choices to satisfy your building's needs.

Unlike various other outside wall cladding systems, building steel panels offer an endless number of style options and are usually less expensive to set up than traditional house siding. They are additionally extremely reduced upkeep.

Abundance of Layout Options

Metal panels can be found in a variety of styles and also surfaces, providing engineers with unlimited opportunities for creating special, custom-made designs. They're likewise durable, light-weight and also reasonably simple to mount.

When choosing a metal wall surface panel system, ensure it has actually passed fire as well as wind examinations. https://www.carsguide.com.au/car-news/why-2022-toyota-landcruiser-300-series-buyers-might-pay-higher-insurance-premiums-to-cover will make sure that the system is correctly shielded as well as can hold up against high wind loads, which can create damage to your structure.

A fantastic way to attain this is by selecting an insulated metal panel (IMP) that has actually undergone NFPA 285, a fire examination from the National Fire Protection Association. This will assist to guarantee your building is secured from fire and also will certainly last longer than a common panel system.

IMPs are a superb option for lots of roof covering and also wall applications, but it's important to make sure that the panels are set up appropriately. Taking a couple of minutes prior to the beginning of a project to assess mounting alignment as well as mount shims will certainly assist stay clear of expensive mistakes.

Low Upkeep

An architectural metal panel system is an effective means to enhance the outside of a building. These panels are available in a wide range of colors, sizes and also coatings to match any type of layout theme or budget.

They are additionally extremely resilient and also reduced upkeep, unlike timber or concrete. While various other products can crack, chip or discolor with time, steel remains strong and also gorgeous.

To maintain metal wall surface cladding looking its finest, see to it to clean it with a soft cloth as well as an option of water as well as neutral cleaning agent. Never ever use a severe industrial detergent or sharp cleansing devices, as these can harm the panels' surface area.

Furthermore, make certain to get rid of any type of particles or standing water from the base of your metal wall surface cladding. This will aid protect against rot and lengthen the life of your cladding.

Energy Performance

The power effectiveness of structures is a crucial factor in reducing emissions that contribute to climate change. To minimize power loss as well as improve a structure's overall power performance, designers as well as specialists are turning to airtight insulated steel panels with optimum thermal resistance.

These panels supply a complete vapor as well as water barrier that inhibits power loss, which can help a building satisfy progressively rigorous power code requirements. Their high R-values allow building groups to satisfy or exceed minimal power efficiency requirements as well as get LEED score points.

Metl-Span's CF Architectural, Mesa, 7.2 Insul-Rib as well as ThermalSafe panels provide extraordinary energy performance in business applications. Along with their remarkable thermal effectiveness, these panels offer a top quality appearance that is cost-competitive with other protected wall surface systems.

Resilience

Whether you're utilizing it for exterior wall surface cladding or trim, or to develop a roofing system deck, architectural metal panel is an incredibly long lasting option. It can hold up against impacts, water damages, and even deterioration.

Resilience is essential when it involves building outsides, because it can avoid structural damage from things like wind, rainfall, as well as hail storm. It can likewise assist secure a building's interior from leaks.

In order to have a sturdy product, it should be coated with a reliable safety layer that can withstand severe weather. A lot of these finishings are available for aluminum, stainless steel as well as copper panels.

Along with durability, steel panel systems need to be crafted for gravity, seismic and wind loading. They additionally require to be attached to a structural framework that can handle flexing or motion due to thermal growth as well as differential motions between panels.

SPOILER ALERT!

If You Remain In The Market For Building Panels, Look No Further Than Mapes

Content author-Jochumsen Sanders

The firm's production group utilizes airborne and ground-based video to show their product line, including architectural panels. It shows the production process as well as the completed item on a consumer's website. The video clip likewise includes a company narrative as well as customer testimonial. The result is an useful, exciting video clip that will have you aligning to acquire Mapes items.

Mapes Panels are a superb selection for any type of building application. These panels have been manufacturing architectural panels for 60 years, and have actually expanded their line over that time. Their building panels are adjustable to match virtually any kind of building coating, including rock, baked enamel, as well as timber. These products can fulfill all local building ordinance, from power efficiency to effect resistance. Along with being durable, Mapes architectural panels are likewise simple to set up, needing little maintenance.

Mapes is likewise a leader in customized building panel services. The company's Mapes-R+ panel has a special face that integrates R-value and developed style. These panels are readily available in a series of densities, from a quarter-inch to four-and-a-half inches. Mapes also uses an architectural panel option for glazed applications. The business's CF Architectural/Horizontal Insulated Metal Panels include a stucco-embossed exterior skin and also a Light Mesa pattern inside skin. visit the following website page can be combined with numerous sizes and shades, and also the firm likewise offers aluminum extrusions to finish a horizontal wall surface system.

If you're thinking about architectural panels, Mapes is the brand to check out. These specialized panels can be utilized in any kind of infill application as well as are exempt from NFPA 285 screening. You can learn more regarding Mapes architectural panels by visiting their cubicle at the Glass Expo Northeast(tm) '22 in Uniondale, NY. Mapes is located in cubicle # 214, as well as will be featuring new products as well as providing free enrollment passes to seminar participants.

Since Mapes is committed to their craft, you can depend on high quality results. The business's panel specialists have years of experience and also can suggest you on panel remedies for your specific project. Their objective is to surpass customer expectations. Setting up Mapes architectural panels eliminates a number of the challenges that are inherent to creating a pre-engineered product. over at this website 'll conserve money and time by staying clear of the complex procedure of panel assembly.

An additional function of Mapes' architectural panels is their insulation. You can locate Mapes-R panels with R=27.9, making them perfect for spandrel, glazing, as well as drape wall surfaces. And also they're readily available in a variety of finishes - from plated to baked enamel - to fit any kind of building finish. In addition to the wide range of architectural surfaces, Mapes also supplies customized panels to match regional building regulations.

Another item offered by Mapes is the Mapes-R+ panel. It uses a combination of an R-value with a developed face. The panel is available in thicknesses as much as 4 1/4 inches. Mapes-R+ protected glass panels are a prominent option amongst designers. Mapes has actually a newly updated website that consists of even more details regarding the Mapes-R+ panel. The firm is an industry leader in building panel remedies and is a trusted source for high-grade protected metal panels.

The firm's production group utilizes airborne and ground-based video to show their product line, including architectural panels. It shows the production process as well as the completed item on a consumer's website. The video clip likewise includes a company narrative as well as customer testimonial. The result is an useful, exciting video clip that will have you aligning to acquire Mapes items.

Mapes Panels are a superb selection for any type of building application. These panels have been manufacturing architectural panels for 60 years, and have actually expanded their line over that time. Their building panels are adjustable to match virtually any kind of building coating, including rock, baked enamel, as well as timber. These products can fulfill all local building ordinance, from power efficiency to effect resistance. Along with being durable, Mapes architectural panels are likewise simple to set up, needing little maintenance.

Mapes is likewise a leader in customized building panel services. The company's Mapes-R+ panel has a special face that integrates R-value and developed style. These panels are readily available in a series of densities, from a quarter-inch to four-and-a-half inches. Mapes also uses an architectural panel option for glazed applications. The business's CF Architectural/Horizontal Insulated Metal Panels include a stucco-embossed exterior skin and also a Light Mesa pattern inside skin. visit the following website page can be combined with numerous sizes and shades, and also the firm likewise offers aluminum extrusions to finish a horizontal wall surface system.

If you're thinking about architectural panels, Mapes is the brand to check out. These specialized panels can be utilized in any kind of infill application as well as are exempt from NFPA 285 screening. You can learn more regarding Mapes architectural panels by visiting their cubicle at the Glass Expo Northeast(tm) '22 in Uniondale, NY. Mapes is located in cubicle # 214, as well as will be featuring new products as well as providing free enrollment passes to seminar participants.

Since Mapes is committed to their craft, you can depend on high quality results. The business's panel specialists have years of experience and also can suggest you on panel remedies for your specific project. Their objective is to surpass customer expectations. Setting up Mapes architectural panels eliminates a number of the challenges that are inherent to creating a pre-engineered product. over at this website 'll conserve money and time by staying clear of the complex procedure of panel assembly.

An additional function of Mapes' architectural panels is their insulation. You can locate Mapes-R panels with R=27.9, making them perfect for spandrel, glazing, as well as drape wall surfaces. And also they're readily available in a variety of finishes - from plated to baked enamel - to fit any kind of building finish. In addition to the wide range of architectural surfaces, Mapes also supplies customized panels to match regional building regulations.

Another item offered by Mapes is the Mapes-R+ panel. It uses a combination of an R-value with a developed face. The panel is available in thicknesses as much as 4 1/4 inches. Mapes-R+ protected glass panels are a prominent option amongst designers. Mapes has actually a newly updated website that consists of even more details regarding the Mapes-R+ panel. The firm is an industry leader in building panel remedies and is a trusted source for high-grade protected metal panels.

SPOILER ALERT!

Mapes Panels Is A Specialist In The Production Of Building Canopies And Also Panels

Article written by-Mohamed Molloy

They use years of experience and understand the latest patterns in the market to fulfill their consumers' needs. The company makes every effort to meet and surpass customer expectations with its product or services. With its assembly team, you will have no stress over the setup process. The specialists at Mapes recognize the process inside and out as well as have the ability to remove inescapable difficulties. Subsequently, you'll save effort and time.

An essential part of the Mapes Panels Workflow team, the Purchasing Agent plays a crucial duty in accomplishing multiple business goals. The Purchasing Agent is in charge of getting material for Mapes manufacturing and makes certain unequaled service to customers. The Acquiring Agent tracks product purchase orders throughout with vendors and maintains documents of materials purchased. Under the supervision of the Workflow & Supply Chain Supervisor, the Investing in Representative additionally fixes product defects. This setting is very closely lined up with production and makes sure that quotes are exact as well as shipment days are satisfied. By keeping strong vendor relationships, the Investing in Agent enables Mapes to satisfy its clients' needs.

One of the very successful Mapes items is the Mapes-R+ Rabbet Edge Panels, which fit flawlessly right into any glazing pocket. As a matter of fact, Mapes-R+ Rabbet Edge Panels can enhance interior insulation up to 400% as well as are readily available in any kind of sort of building surface. Along with using higher indoor insulation, Mapes-R+ panels can additionally enhance aesthetics. The firm's web site also features extensive photos of Mapes Panels in use.

Suggested Webpage are one more product from Mapes. Mapes-R infill panels supply premium thermal efficiency enhancement and are optimal for curtain walls, spandrels, and glazing applications. The panels come in a variety of architectural finishes such as baked enamel as well as anodized. They can be customized to meet building ordinance requirements for fire and also audio resistance. These panels also fulfill all other power effectiveness requirements. If you intend to use Mapes-R infill panels, you'll more than happy to understand that you can tailor these panels according to your requirements.

Mapes Panels is a leading maker of protected steel panels. The Mapes-R+ is a prominent selection among engineers. Recommended Internet page and making quality have made it the sector leader in the manufacturing of building panels. Its custom solutions are made from state-of-the-art materials and also shielded metal. You can see more information on the Mapes-R+ panel on its internet site. You can additionally find even more details regarding its various other products on the Mapes-R+ panel by checking out the company's web site.

They use years of experience and understand the latest patterns in the market to fulfill their consumers' needs. The company makes every effort to meet and surpass customer expectations with its product or services. With its assembly team, you will have no stress over the setup process. The specialists at Mapes recognize the process inside and out as well as have the ability to remove inescapable difficulties. Subsequently, you'll save effort and time.

An essential part of the Mapes Panels Workflow team, the Purchasing Agent plays a crucial duty in accomplishing multiple business goals. The Purchasing Agent is in charge of getting material for Mapes manufacturing and makes certain unequaled service to customers. The Acquiring Agent tracks product purchase orders throughout with vendors and maintains documents of materials purchased. Under the supervision of the Workflow & Supply Chain Supervisor, the Investing in Representative additionally fixes product defects. This setting is very closely lined up with production and makes sure that quotes are exact as well as shipment days are satisfied. By keeping strong vendor relationships, the Investing in Agent enables Mapes to satisfy its clients' needs.

One of the very successful Mapes items is the Mapes-R+ Rabbet Edge Panels, which fit flawlessly right into any glazing pocket. As a matter of fact, Mapes-R+ Rabbet Edge Panels can enhance interior insulation up to 400% as well as are readily available in any kind of sort of building surface. Along with using higher indoor insulation, Mapes-R+ panels can additionally enhance aesthetics. The firm's web site also features extensive photos of Mapes Panels in use.

Suggested Webpage are one more product from Mapes. Mapes-R infill panels supply premium thermal efficiency enhancement and are optimal for curtain walls, spandrels, and glazing applications. The panels come in a variety of architectural finishes such as baked enamel as well as anodized. They can be customized to meet building ordinance requirements for fire and also audio resistance. These panels also fulfill all other power effectiveness requirements. If you intend to use Mapes-R infill panels, you'll more than happy to understand that you can tailor these panels according to your requirements.

Mapes Panels is a leading maker of protected steel panels. The Mapes-R+ is a prominent selection among engineers. Recommended Internet page and making quality have made it the sector leader in the manufacturing of building panels. Its custom solutions are made from state-of-the-art materials and also shielded metal. You can see more information on the Mapes-R+ panel on its internet site. You can additionally find even more details regarding its various other products on the Mapes-R+ panel by checking out the company's web site.

SPOILER ALERT!

Why Aluminium Cover Is Best Over Various Other Materials?

Content by-Coble Scarborough

The advantages of an aluminum canopy are numerous. First of all, it's light-weight, with less than one-third the weight of steel. Because of this, the aluminum structure supplies better strength and also sturdiness. On top of that, the structure is conveniently customized, suggesting you can transform the colour, product, and rebrand it to suit your style. Finally, an aluminium canopy has the ability to carry fluids as well as other items. The benefits of an aluminium cover are numerous, and you will certainly rejoice you picked it over other products.

Second of all, an Aluminium Canopy is a superb canvas for your imaginative ideas. You can tailor the interior along with the outside to mirror your brand name or marketing message. The huge flat surface is excellent for signwriting and also is readily available in Black or White powdercoat finishes as requirement. During the process, the canopy is covered making use of a cutting edge powder finishing booth. This process offers a durable finish that will certainly last for many years.

Finally, an Aluminium Canopy is extremely protected, with a copyrighted slam locking system that is integrated with main vehicle securing. In addition, the door is made from strong aluminium, stopping prying eyes from seeing the within your equipment. Lastly, an Aluminium Canopy is much more safe and secure than a fibreglass or ABS cover, as its frame is made from a strong material that will not break easily.

Last but not least, an Aluminium Cover is much lighter than the majority of products. However, it still requires expert setup, so make sure to locate a professional company that provides setup. If you're stressed over expense, check out evaluations on the internet and contrast various business' costs, experience, as well as installment technology. You'll likely be pleased with your acquisition! The benefits of an Aluminium Cover Over Various Other Materials

Aluminium Canopies are additionally a prominent choice for utes. These flexible structures can be customised to match your demands, whether for work or recreation. With an aluminium cover, you can easily add shelving, drawers, device boxes, trays, and also even a refrigerator slide if you desire. The possibilities are unlimited. And don't fail to remember that it can likewise be a practical enhancement to your ute. For https://www.columbian.com/news/2021/nov/22/cultivating-the-citys-tree-canopy-vancouver-slowly-grows-goal/ , you can use it as a workshop with drawers as well as trays for your tools, and also put your groceries inside!

The advantages of an aluminum canopy are numerous. First of all, it's light-weight, with less than one-third the weight of steel. Because of this, the aluminum structure supplies better strength and also sturdiness. On top of that, the structure is conveniently customized, suggesting you can transform the colour, product, and rebrand it to suit your style. Finally, an aluminium canopy has the ability to carry fluids as well as other items. The benefits of an aluminium cover are numerous, and you will certainly rejoice you picked it over other products.

Second of all, an Aluminium Canopy is a superb canvas for your imaginative ideas. You can tailor the interior along with the outside to mirror your brand name or marketing message. The huge flat surface is excellent for signwriting and also is readily available in Black or White powdercoat finishes as requirement. During the process, the canopy is covered making use of a cutting edge powder finishing booth. This process offers a durable finish that will certainly last for many years.

Finally, an Aluminium Canopy is extremely protected, with a copyrighted slam locking system that is integrated with main vehicle securing. In addition, the door is made from strong aluminium, stopping prying eyes from seeing the within your equipment. Lastly, an Aluminium Canopy is much more safe and secure than a fibreglass or ABS cover, as its frame is made from a strong material that will not break easily.

Last but not least, an Aluminium Cover is much lighter than the majority of products. However, it still requires expert setup, so make sure to locate a professional company that provides setup. If you're stressed over expense, check out evaluations on the internet and contrast various business' costs, experience, as well as installment technology. You'll likely be pleased with your acquisition! The benefits of an Aluminium Cover Over Various Other Materials

Aluminium Canopies are additionally a prominent choice for utes. These flexible structures can be customised to match your demands, whether for work or recreation. With an aluminium cover, you can easily add shelving, drawers, device boxes, trays, and also even a refrigerator slide if you desire. The possibilities are unlimited. And don't fail to remember that it can likewise be a practical enhancement to your ute. For https://www.columbian.com/news/2021/nov/22/cultivating-the-citys-tree-canopy-vancouver-slowly-grows-goal/ , you can use it as a workshop with drawers as well as trays for your tools, and also put your groceries inside!

SPOILER ALERT!

Below Are The Advantages Of Aluminum Home Window Awnings

Written by-Andreasen Thaysen

When setting up aluminum home window awnings, the initial step is establishing the size and also size of the awning. After that, connect stringer devices to the structure utilizing return arms. These ought to fit comfortably in the awning's bottom corners. Utilizing a level as well as a tape measure, note the place of each brace, and then drill the holes. After that, install the awning. The installation procedure need to be very easy and quick.

In addition to visual advantages, home window awnings can additionally be energy-efficient. By blocking the sun's UV rays, these awnings can reduce the within temperature of a home by nearly seventy-seven percent. They can also reduce solar warmth gain by as long as 77 percent on windows with a westward alignment. While they do call for periodic upkeep, aluminum home window awnings are generally maintenance-free. United Light weight aluminum provides window awning installation as well as repair solutions in the Phoenix city area.

For safety and security, light weight aluminum home window awnings can likewise be utilized as tornado shutters. Given that they won't corrosion or dent, light weight aluminum home window awnings can be made use of outdoors. The adjustable support arms permit a custom-made slant to block the sunlight's rays. https://www.diigo.com/user/mapescanopies to light weight aluminum window awnings is that they are exceptionally durable and also won't fall apart. They will not rust or warp, as well as are a perfect balance in between cost and also strength.

Aluminum home window awnings are a terrific option for securing home windows from the sun. Not only do they shield you and also your automobile from UV rays, they likewise contribute to the outside look of your residence. As well as they are also inexpensive. Many light weight aluminum window awnings are simple to install, don't need to be tarnished, and don't call for maintenance. And due to the fact that they're so reduced upkeep, they will not rot or warp.

For a standard appearance, classic aluminum home window awnings will certainly enhance the design of your residence. These awnings are lightweight, durable, as well as virtually maintenance-free. They additionally can be found in a variety of colors and also styles, as well as enhance the style of your home. As well as if you're trying to find a new awning, you can go to the workplaces of Superior Awning. outside awnings amongst the most sturdy as well as trusted in the sector.

Another benefit of aluminum home window awnings is their low maintenance and also many color options. You can easily match the colors and style of your residence by picking an aluminum home window awning with a base color as well as a feature shade. The aluminum home window awnings are very easy to mount as well as can be placed over the home window or below the rain gutter piping. In addition to shade and sun security, they are an appealing and also hassle-free home window treatment for any home.

Another advantage of light weight aluminum awnings is that they will not tear or flex like canvas as well as material awnings. They're additionally a lot more sturdy, permitting them to keep up year-round even in the harshest of weather. They do not promote mold and mildew development, and also their wind scores range between 130 and 140 mph. Furthermore, aluminum window awnings are simple to maintain, and water drains pipes easily from them. They additionally do not trap water and also prevent leaf accumulation.

When mounting aluminum home window awnings, see to it to examine the specifications. Whether you're going for a stationary awning or a roll-up awning, make certain it can manage the quantity of snow your area commonly obtains. And also if you stay in a location with a lot of snow, you'll more than happy to learn that aluminum awnings are also durable as well as immune to the cold. As a matter of fact, some designs have snow-reflecting capacities!

Aluminum home window awnings are a wonderful choice for homeowners who want to add aesthetic appeal to their home without breaking the financial institution. These awnings decrease direct sunshine, supply color, and shield the exterior siding from debris. Additionally, they're a whole lot less expensive than canvas awnings. If you're seeking a premium awning, make certain to have a look at these testimonials. The cost is normally right in the middle.

When setting up aluminum home window awnings, the initial step is establishing the size and also size of the awning. After that, connect stringer devices to the structure utilizing return arms. These ought to fit comfortably in the awning's bottom corners. Utilizing a level as well as a tape measure, note the place of each brace, and then drill the holes. After that, install the awning. The installation procedure need to be very easy and quick.

In addition to visual advantages, home window awnings can additionally be energy-efficient. By blocking the sun's UV rays, these awnings can reduce the within temperature of a home by nearly seventy-seven percent. They can also reduce solar warmth gain by as long as 77 percent on windows with a westward alignment. While they do call for periodic upkeep, aluminum home window awnings are generally maintenance-free. United Light weight aluminum provides window awning installation as well as repair solutions in the Phoenix city area.

For safety and security, light weight aluminum home window awnings can likewise be utilized as tornado shutters. Given that they won't corrosion or dent, light weight aluminum home window awnings can be made use of outdoors. The adjustable support arms permit a custom-made slant to block the sunlight's rays. https://www.diigo.com/user/mapescanopies to light weight aluminum window awnings is that they are exceptionally durable and also won't fall apart. They will not rust or warp, as well as are a perfect balance in between cost and also strength.

Aluminum home window awnings are a terrific option for securing home windows from the sun. Not only do they shield you and also your automobile from UV rays, they likewise contribute to the outside look of your residence. As well as they are also inexpensive. Many light weight aluminum window awnings are simple to install, don't need to be tarnished, and don't call for maintenance. And due to the fact that they're so reduced upkeep, they will not rot or warp.

For a standard appearance, classic aluminum home window awnings will certainly enhance the design of your residence. These awnings are lightweight, durable, as well as virtually maintenance-free. They additionally can be found in a variety of colors and also styles, as well as enhance the style of your home. As well as if you're trying to find a new awning, you can go to the workplaces of Superior Awning. outside awnings amongst the most sturdy as well as trusted in the sector.

Another benefit of aluminum home window awnings is their low maintenance and also many color options. You can easily match the colors and style of your residence by picking an aluminum home window awning with a base color as well as a feature shade. The aluminum home window awnings are very easy to mount as well as can be placed over the home window or below the rain gutter piping. In addition to shade and sun security, they are an appealing and also hassle-free home window treatment for any home.

Another advantage of light weight aluminum awnings is that they will not tear or flex like canvas as well as material awnings. They're additionally a lot more sturdy, permitting them to keep up year-round even in the harshest of weather. They do not promote mold and mildew development, and also their wind scores range between 130 and 140 mph. Furthermore, aluminum window awnings are simple to maintain, and water drains pipes easily from them. They additionally do not trap water and also prevent leaf accumulation.

When mounting aluminum home window awnings, see to it to examine the specifications. Whether you're going for a stationary awning or a roll-up awning, make certain it can manage the quantity of snow your area commonly obtains. And also if you stay in a location with a lot of snow, you'll more than happy to learn that aluminum awnings are also durable as well as immune to the cold. As a matter of fact, some designs have snow-reflecting capacities!

Aluminum home window awnings are a wonderful choice for homeowners who want to add aesthetic appeal to their home without breaking the financial institution. These awnings decrease direct sunshine, supply color, and shield the exterior siding from debris. Additionally, they're a whole lot less expensive than canvas awnings. If you're seeking a premium awning, make certain to have a look at these testimonials. The cost is normally right in the middle.

SPOILER ALERT!

Right Here Are A Couple Of Reasons That You Need To Think About An Aluminium Canopy For Your Ute

Written by-Rosenberg Fletcher

An aluminium cover is a wonderful choice for various reasons. Not only is it light-weight, yet it also secures your items inside from the components, consisting of rainfall and sunshine. Its aluminium building likewise decreases the opportunity of burglary, and its enhanced security attributes make it a safe choice for storing your valuables. You will not be disappointed!

Lightweight - A light weight aluminum canopy weighs less than one third of the weight of a similar steel cover, making it a wonderful option for lightweight frameworks. Lightweight structures likewise aid to lower project material as well as installment prices. The panels of an aluminum cover are furnished with internal water drainage, and water is released via downsouts, breams, as well as columns. These elements minimize the overall weight and expenditure of an aluminium canopy, along with its maintenance.

Read the Full Report - While an aluminium cover evaluates a little greater than other products, it is still more light-weight than a fibreglass canopy. The light-weight material enables the cover to have the optimal equilibrium, which assists your car's engine and also your car. Having a lighter canopy is also easier to tow, which means less pressure on the engine. Therefore, it's a terrific option for long days of traveling and long haul journeys.

Australian made - The MITS Alloy range of canopies are made in Australia from 100% Australian aluminium. spandrel panel detail are powder-coated and also come with a lifetime warranty against problems in production. They are also Australian-made, as well as are backed by a solid guarantee versus corrosion as well as rust. The MITS Alloy range is known for its high quality and also resilience. In addition, you will not be overlooked if you require a replacement.

Utility - Lots of people utilize a covers to store tools, materials, and devices in their ute. Regardless of its dimension as well as weight, it is better than a regular roofing system or a common roof to safeguard your freight. It can even enhance your car's resale worth. You can also add a fridge slide or shelving to your aluminum cover. That's pretty amazing. There are lots of usages for an aluminium canopy.

Looks - Light weight aluminum canopies make any outside room appearance wonderful. They are durable and also be available in numerous colors. They're a fantastic choice for high-traffic locations. These canopies cover the area in between two structures or lead up to the entrance. They additionally shield from the elements while offering an eye-catching and practical space. Whether you're searching for a fashionable patio cover or a practical carport, an aluminum cover is a great selection.

Rate - In addition to its aesthetic appeal, an aluminium canopy likewise supplies a sturdy option for ute owners. Prices vary from regarding $1500 for a half-canopy to five-thousand dollars for a fully-fitted canopy. Prices vary greatly based upon style, however a brand-new cover can conveniently be bought at a rate below its cost. You can likewise buy pre-owned aluminium canopies, which are likewise an excellent choice if you can not afford an all new cover.

Aluminium is a strong metal that becomes even stronger in cold temperature levels. This makes it excellent for outside usage in the UK, as it will not corrosion or rot. Besides its fundamental anti-corrosive properties, aluminium is additionally powder covered for aesthetic objectives. Its reflective buildings help secure light, making it perfect for outside usage. And it's fire-retardant as well as does not give off poisonous fumes.

To prevent leaks, you should seal the locations around the tub and also tray. While an aluminium ute canopy can maintain rainfall as well as snow out, it will not avoid water from getting in the ute. Thus, you must secure the locations around these trouble spots with rubber or foam sealing. A special adhesive can additionally be utilized. This will aid keep the ute dry and without water. Finally, ensure you don't utilize chemicals or any kind of cleaners.

An aluminium cover is a wonderful choice for various reasons. Not only is it light-weight, yet it also secures your items inside from the components, consisting of rainfall and sunshine. Its aluminium building likewise decreases the opportunity of burglary, and its enhanced security attributes make it a safe choice for storing your valuables. You will not be disappointed!

Lightweight - A light weight aluminum canopy weighs less than one third of the weight of a similar steel cover, making it a wonderful option for lightweight frameworks. Lightweight structures likewise aid to lower project material as well as installment prices. The panels of an aluminum cover are furnished with internal water drainage, and water is released via downsouts, breams, as well as columns. These elements minimize the overall weight and expenditure of an aluminium canopy, along with its maintenance.

Read the Full Report - While an aluminium cover evaluates a little greater than other products, it is still more light-weight than a fibreglass canopy. The light-weight material enables the cover to have the optimal equilibrium, which assists your car's engine and also your car. Having a lighter canopy is also easier to tow, which means less pressure on the engine. Therefore, it's a terrific option for long days of traveling and long haul journeys.

Australian made - The MITS Alloy range of canopies are made in Australia from 100% Australian aluminium. spandrel panel detail are powder-coated and also come with a lifetime warranty against problems in production. They are also Australian-made, as well as are backed by a solid guarantee versus corrosion as well as rust. The MITS Alloy range is known for its high quality and also resilience. In addition, you will not be overlooked if you require a replacement.

Utility - Lots of people utilize a covers to store tools, materials, and devices in their ute. Regardless of its dimension as well as weight, it is better than a regular roofing system or a common roof to safeguard your freight. It can even enhance your car's resale worth. You can also add a fridge slide or shelving to your aluminum cover. That's pretty amazing. There are lots of usages for an aluminium canopy.

Looks - Light weight aluminum canopies make any outside room appearance wonderful. They are durable and also be available in numerous colors. They're a fantastic choice for high-traffic locations. These canopies cover the area in between two structures or lead up to the entrance. They additionally shield from the elements while offering an eye-catching and practical space. Whether you're searching for a fashionable patio cover or a practical carport, an aluminum cover is a great selection.

Rate - In addition to its aesthetic appeal, an aluminium canopy likewise supplies a sturdy option for ute owners. Prices vary from regarding $1500 for a half-canopy to five-thousand dollars for a fully-fitted canopy. Prices vary greatly based upon style, however a brand-new cover can conveniently be bought at a rate below its cost. You can likewise buy pre-owned aluminium canopies, which are likewise an excellent choice if you can not afford an all new cover.

Aluminium is a strong metal that becomes even stronger in cold temperature levels. This makes it excellent for outside usage in the UK, as it will not corrosion or rot. Besides its fundamental anti-corrosive properties, aluminium is additionally powder covered for aesthetic objectives. Its reflective buildings help secure light, making it perfect for outside usage. And it's fire-retardant as well as does not give off poisonous fumes.

To prevent leaks, you should seal the locations around the tub and also tray. While an aluminium ute canopy can maintain rainfall as well as snow out, it will not avoid water from getting in the ute. Thus, you must secure the locations around these trouble spots with rubber or foam sealing. A special adhesive can additionally be utilized. This will aid keep the ute dry and without water. Finally, ensure you don't utilize chemicals or any kind of cleaners.

SPOILER ALERT!

Why Aluminium Cover Is Best Over Other Materials?

Created by-Coble Kinney

The benefits of an aluminum canopy are many. Firstly, https://trello.com/mapespanels/activity , with less than one-third the weight of steel. Thus, the aluminum structure supplies better toughness and also durability. Furthermore, the structure is easily customized, meaning you can change the colour, product, and also rebrand it to suit your style. Finally, an aluminium canopy is able to lug fluids and also other products. The advantages of an aluminium cover are numerous, and you will rejoice you selected it over various other materials.

Second of all, an Aluminium Cover is a superb canvas for your imaginative concepts. You can customize the inside along with the outside to mirror your brand or advertising message. The huge flat surface area is best for signwriting and also is available in Black or White powdercoat finishes as requirement. During the process, the cover is coated making use of a cutting edge powder finish cubicle. This procedure provides a sturdy surface that will certainly last for several years.

Third, an Aluminium Cover is very protected, with a trademarked slam securing system that is incorporated with central automobile securing. Furthermore, the door is made from strong aluminium, avoiding prying eyes from seeing the inside of your equipment. Finally, an Aluminium Canopy is much more protected than a fibreglass or abdominal canopy, as its framework is made of a strong product that will not break easily.

Finally, an Aluminium Cover is much lighter than many products. Nonetheless, it still calls for specialist installment, so make sure to discover a professional firm that supplies installation. If Get Source stressed over expense, take a look at reviews on-line as well as contrast different business' prices, experience, and also setup innovation. You'll likely be pleased with your acquisition! The benefits of an Aluminium Cover Over Various Other Materials

Aluminium Canopies are additionally a prominent selection for utes. These functional structures can be tailor-maked to suit your demands, whether for work or leisure. With an aluminium canopy, you can conveniently add shelving, cabinets, device boxes, trays, and also even a fridge slide if you wish. The possibilities are unlimited. And also do not forget that it can additionally be an useful enhancement to your ute. For example, you can use it as a workshop with cabinets and also trays for your tools, and also put your grocery stores inside!

The benefits of an aluminum canopy are many. Firstly, https://trello.com/mapespanels/activity , with less than one-third the weight of steel. Thus, the aluminum structure supplies better toughness and also durability. Furthermore, the structure is easily customized, meaning you can change the colour, product, and also rebrand it to suit your style. Finally, an aluminium canopy is able to lug fluids and also other products. The advantages of an aluminium cover are numerous, and you will rejoice you selected it over various other materials.

Second of all, an Aluminium Cover is a superb canvas for your imaginative concepts. You can customize the inside along with the outside to mirror your brand or advertising message. The huge flat surface area is best for signwriting and also is available in Black or White powdercoat finishes as requirement. During the process, the cover is coated making use of a cutting edge powder finish cubicle. This procedure provides a sturdy surface that will certainly last for several years.

Third, an Aluminium Cover is very protected, with a trademarked slam securing system that is incorporated with central automobile securing. Furthermore, the door is made from strong aluminium, avoiding prying eyes from seeing the inside of your equipment. Finally, an Aluminium Canopy is much more protected than a fibreglass or abdominal canopy, as its framework is made of a strong product that will not break easily.

Finally, an Aluminium Cover is much lighter than many products. Nonetheless, it still calls for specialist installment, so make sure to discover a professional firm that supplies installation. If Get Source stressed over expense, take a look at reviews on-line as well as contrast different business' prices, experience, and also setup innovation. You'll likely be pleased with your acquisition! The benefits of an Aluminium Cover Over Various Other Materials

Aluminium Canopies are additionally a prominent selection for utes. These functional structures can be tailor-maked to suit your demands, whether for work or leisure. With an aluminium canopy, you can conveniently add shelving, cabinets, device boxes, trays, and also even a fridge slide if you wish. The possibilities are unlimited. And also do not forget that it can additionally be an useful enhancement to your ute. For example, you can use it as a workshop with cabinets and also trays for your tools, and also put your grocery stores inside!

SPOILER ALERT!

Continue Reading To Read More Regarding The Advantages Of Aluminium

Article writer-Tyler Madden

When choosing a canopy for your ute, aluminium is a great choice. Not only is aluminium light-weight, yet it also has many advantages over other products, consisting of lower fuel consumption and also maintenance. In addition, contrasted to fibreglass, aluminium is less complicated to tow and also is less most likely to influence your car's gas economic situation. There are several various other reasons to select an aluminium canopy for your ute, as well.

The primary benefit of an aluminium canopy is its lightweight style. Although a steel cover is much heavier, the aluminium canopy does not impact the weight of the vehicle. It supplies the exact same degree of security as steel covers, but does not affect its gas consumption. Its lightweight building and construction ensures that you will have the ability to appreciate the shade of an aluminium canopy for as long as you want. Other than this, aluminium canopies are also a terrific selection for people who reside in climates where rain and also snow prevail.

Unlike steel, light weight aluminum is exceptionally light-weight, evaluating concerning a 3rd of the weight. This implies reduced project product and installation prices. In addition, the light weight of a light weight aluminum canopy indicates simple installation and is environmentally friendly, which is essential in the Southwest. Other than its lightweight as well as low cost, a light weight aluminum canopy additionally looks wonderful as well as includes worth to your structure. It can additionally be tailored with shades and various other functions. For example, the bottom cover is available in kelly eco-friendly and also sand shade.

When selecting an aluminium cover, remember to check the products utilized and also the manufacturer's service warranty for the product. Several of these companies provide free trials. If you aren't satisfied with the maker's product or service, do not be reluctant to return it. You can additionally get a cost-free quote from them. If you have any type of questions, please do not hesitate to speak to the maker straight. You can call the firm to buy an aluminium cover.

An additional benefit of aluminium canopies is their versatility. They are great for transferring devices, and also they often tend to be a lot more durable than other products. Frequently, https://www.gizmochina.com/2021/11/03/honda-latest-e-bike-gyro-canopye-three-wheeled-scooter-roof/ use them. A ute canopy is a structure mounted on the back of a ute. These covers are usually furnished with wall surfaces and doors for simple accessibility and also safety. You can also have a refrigerator slide installed in one. There are numerous various other advantages to making use of an aluminium cover for your ute.

Besides giving color, a light weight aluminum cover adds architectural beauty to a structure. You can select from a variety of different dimensions as well as shades, relying on your demands. Light weight aluminum covers can be used as carports or outdoor patio covers, and can also work as sunlight displays or carports. These canopies are light-weight, sturdy, and be available in a vast array of shades. If you desire an even more modern design, you can choose an aluminium canopy that protrudes right from the structure.

When you've picked an aluminium canopy for your ute, you prepare to make your initial journey. Yet prior to you head out, don't ignore the roof-rack that will certainly safeguard your devices. In addition to being durable, this will aid you conserve money. And you can repaint the aluminium cover to match the interior of your vehicle. There's actually no drawback to an excellent canopy, so don't hesitate to get one!

An additional advantage of aluminium is its high strength-to-weight ratio. Because https://mapespanels.blogspot.com/ does not corrosion and also does not rot, it is very durable. It likewise naturally generates an oxide finish that shields it from unsafe UV rays and also rot. And if visual appeals are your major concern, you can opt for a powder-coated aluminium cover. In addition, aluminium has reflective homes that protect light, radio waves, and infrared radiation. Moreover, it's fireproof as well as does not give off any type of toxic fumes when oxidized.

When choosing a canopy for your ute, aluminium is a great choice. Not only is aluminium light-weight, yet it also has many advantages over other products, consisting of lower fuel consumption and also maintenance. In addition, contrasted to fibreglass, aluminium is less complicated to tow and also is less most likely to influence your car's gas economic situation. There are several various other reasons to select an aluminium canopy for your ute, as well.

The primary benefit of an aluminium canopy is its lightweight style. Although a steel cover is much heavier, the aluminium canopy does not impact the weight of the vehicle. It supplies the exact same degree of security as steel covers, but does not affect its gas consumption. Its lightweight building and construction ensures that you will have the ability to appreciate the shade of an aluminium canopy for as long as you want. Other than this, aluminium canopies are also a terrific selection for people who reside in climates where rain and also snow prevail.

Unlike steel, light weight aluminum is exceptionally light-weight, evaluating concerning a 3rd of the weight. This implies reduced project product and installation prices. In addition, the light weight of a light weight aluminum canopy indicates simple installation and is environmentally friendly, which is essential in the Southwest. Other than its lightweight as well as low cost, a light weight aluminum canopy additionally looks wonderful as well as includes worth to your structure. It can additionally be tailored with shades and various other functions. For example, the bottom cover is available in kelly eco-friendly and also sand shade.

When selecting an aluminium cover, remember to check the products utilized and also the manufacturer's service warranty for the product. Several of these companies provide free trials. If you aren't satisfied with the maker's product or service, do not be reluctant to return it. You can additionally get a cost-free quote from them. If you have any type of questions, please do not hesitate to speak to the maker straight. You can call the firm to buy an aluminium cover.

An additional benefit of aluminium canopies is their versatility. They are great for transferring devices, and also they often tend to be a lot more durable than other products. Frequently, https://www.gizmochina.com/2021/11/03/honda-latest-e-bike-gyro-canopye-three-wheeled-scooter-roof/ use them. A ute canopy is a structure mounted on the back of a ute. These covers are usually furnished with wall surfaces and doors for simple accessibility and also safety. You can also have a refrigerator slide installed in one. There are numerous various other advantages to making use of an aluminium cover for your ute.

Besides giving color, a light weight aluminum cover adds architectural beauty to a structure. You can select from a variety of different dimensions as well as shades, relying on your demands. Light weight aluminum covers can be used as carports or outdoor patio covers, and can also work as sunlight displays or carports. These canopies are light-weight, sturdy, and be available in a vast array of shades. If you desire an even more modern design, you can choose an aluminium canopy that protrudes right from the structure.

When you've picked an aluminium canopy for your ute, you prepare to make your initial journey. Yet prior to you head out, don't ignore the roof-rack that will certainly safeguard your devices. In addition to being durable, this will aid you conserve money. And you can repaint the aluminium cover to match the interior of your vehicle. There's actually no drawback to an excellent canopy, so don't hesitate to get one!

An additional advantage of aluminium is its high strength-to-weight ratio. Because https://mapespanels.blogspot.com/ does not corrosion and also does not rot, it is very durable. It likewise naturally generates an oxide finish that shields it from unsafe UV rays and also rot. And if visual appeals are your major concern, you can opt for a powder-coated aluminium cover. In addition, aluminium has reflective homes that protect light, radio waves, and infrared radiation. Moreover, it's fireproof as well as does not give off any type of toxic fumes when oxidized.

SPOILER ALERT!

Right Here Are The Advantages Of Aluminum Home Window Awnings

Article writer-West Thaysen

When mounting aluminum window awnings, the primary step is establishing the length as well as width of the awning. After that, affix stringer devices to the framework making use of return arms. These must fit comfortably in the awning's lower edges. Making use of a degree as well as a measuring tape, note the area of each brace, and afterwards drill the holes. Then, mount the awning. The setup procedure need to be easy as well as fast.

In addition to aesthetic advantages, home window awnings can also be energy-efficient. By blocking the sun's UV rays, these awnings can reduce the within temperature of a home by almost seventy-seven percent. They can likewise decrease solar heat gain by as much as 77 percent on windows with a westward alignment. While they do call for periodic upkeep, light weight aluminum window awnings are typically maintenance-free. United Aluminum supplies home window awning installation and repair service services in the Phoenix city location.

For safety, aluminum home window awnings can additionally be made use of as tornado shutters. Considering that they won't corrosion or damage, light weight aluminum home window awnings can be used outdoors. The adjustable support arms allow for a custom-made slant to obstruct the sunlight's rays. An additional benefit to aluminum home window awnings is that they are very sturdy and will not crumble. They will certainly not corrosion or warp, as well as are an ideal balance between cost and strength.

vertical sun shades are a wonderful option for shielding windows from the sun. Not just do they secure you as well as your automobile from UV rays, they also contribute to the external appearance of your house. And they are additionally economical. The majority of light weight aluminum window awnings are simple to set up, don't need to be discolored, as well as don't require upkeep. And since they're so reduced upkeep, they won't rot or warp.

For a conventional look, traditional aluminum window awnings will complement the design of your house. These awnings are light-weight, long lasting, and also practically maintenance-free. They also come in a variety of colors and also styles, and also enhance the design of your property. And if you're searching for a new awning, you can visit the offices of Superior Awning. They're among the most sturdy as well as dependable in the industry.

Another benefit of light weight aluminum home window awnings is their reduced upkeep and also countless color selections. You can conveniently match the shades and design of your house by selecting a light weight aluminum home window awning with a base color and a function color. https://coub.com/mapescanopies are easy to set up and also can be positioned over the window or listed below the gutter piping. Along with shade and sunlight defense, they are an appealing and hassle-free home window therapy for any kind of residence.

An additional advantage of light weight aluminum awnings is that they will not tear or bend like canvas as well as fabric awnings. They're additionally a lot more durable, enabling them to keep up year-round even in the harshest of climate condition. They don't advertise mold growth, and their wind scores range between 130 and 140 miles per hour. Furthermore, aluminum window awnings are simple to maintain, as well as water drains conveniently from them. They additionally do not trap water as well as prevent leaf accumulation.

When mounting aluminum home window awnings, ensure to inspect the specs. Whether you're going with a stationary awning or a roll-up awning, make sure it can handle the amount of snow your area usually obtains. As well as if you live in a location with a lot of snow, you'll be happy to find out that aluminum awnings are likewise long lasting as well as resistant to the cold. As a matter of fact, some models have snow-reflecting abilities!

Light weight aluminum window awnings are a terrific selection for property owners who intend to add curb appeal to their house without breaking the bank. These awnings minimize straight sunlight, offer shade, as well as secure the exterior siding from particles. In addition, they're a whole lot more affordable than canvas awnings. If you're seeking a top notch awning, make certain to take a look at these reviews. The price is typically ideal between.

When mounting aluminum window awnings, the primary step is establishing the length as well as width of the awning. After that, affix stringer devices to the framework making use of return arms. These must fit comfortably in the awning's lower edges. Making use of a degree as well as a measuring tape, note the area of each brace, and afterwards drill the holes. Then, mount the awning. The setup procedure need to be easy as well as fast.

In addition to aesthetic advantages, home window awnings can also be energy-efficient. By blocking the sun's UV rays, these awnings can reduce the within temperature of a home by almost seventy-seven percent. They can likewise decrease solar heat gain by as much as 77 percent on windows with a westward alignment. While they do call for periodic upkeep, light weight aluminum window awnings are typically maintenance-free. United Aluminum supplies home window awning installation and repair service services in the Phoenix city location.

For safety, aluminum home window awnings can additionally be made use of as tornado shutters. Considering that they won't corrosion or damage, light weight aluminum home window awnings can be used outdoors. The adjustable support arms allow for a custom-made slant to obstruct the sunlight's rays. An additional benefit to aluminum home window awnings is that they are very sturdy and will not crumble. They will certainly not corrosion or warp, as well as are an ideal balance between cost and strength.

vertical sun shades are a wonderful option for shielding windows from the sun. Not just do they secure you as well as your automobile from UV rays, they also contribute to the external appearance of your house. And they are additionally economical. The majority of light weight aluminum window awnings are simple to set up, don't need to be discolored, as well as don't require upkeep. And since they're so reduced upkeep, they won't rot or warp.

For a conventional look, traditional aluminum window awnings will complement the design of your house. These awnings are light-weight, long lasting, and also practically maintenance-free. They also come in a variety of colors and also styles, and also enhance the design of your property. And if you're searching for a new awning, you can visit the offices of Superior Awning. They're among the most sturdy as well as dependable in the industry.

Another benefit of light weight aluminum home window awnings is their reduced upkeep and also countless color selections. You can conveniently match the shades and design of your house by selecting a light weight aluminum home window awning with a base color and a function color. https://coub.com/mapescanopies are easy to set up and also can be positioned over the window or listed below the gutter piping. Along with shade and sunlight defense, they are an appealing and hassle-free home window therapy for any kind of residence.

An additional advantage of light weight aluminum awnings is that they will not tear or bend like canvas as well as fabric awnings. They're additionally a lot more durable, enabling them to keep up year-round even in the harshest of climate condition. They don't advertise mold growth, and their wind scores range between 130 and 140 miles per hour. Furthermore, aluminum window awnings are simple to maintain, as well as water drains conveniently from them. They additionally do not trap water as well as prevent leaf accumulation.

When mounting aluminum home window awnings, ensure to inspect the specs. Whether you're going with a stationary awning or a roll-up awning, make sure it can handle the amount of snow your area usually obtains. As well as if you live in a location with a lot of snow, you'll be happy to find out that aluminum awnings are likewise long lasting as well as resistant to the cold. As a matter of fact, some models have snow-reflecting abilities!

Light weight aluminum window awnings are a terrific selection for property owners who intend to add curb appeal to their house without breaking the bank. These awnings minimize straight sunlight, offer shade, as well as secure the exterior siding from particles. In addition, they're a whole lot more affordable than canvas awnings. If you're seeking a top notch awning, make certain to take a look at these reviews. The price is typically ideal between.

SPOILER ALERT!

How To Choose The Light Weight Aluminum Home Window Awnings

Authored by-Ottosen Dempsey

When selecting aluminum home window awnings, you can locate them in a variety of colors as well as styles. In order to mount one, the awnings must be connected to the home window framework between the stringers. Once the awning has actually been attached, you can begin extending the awning from the top to the bottom. Make certain to safeguard it near the bottom. You can utilize screws to secure the awning to the home window structure. You may require to add added support braces over the window relying on its dimension.

In addition to being attractive and convenient, light weight aluminum home window awnings are also very resilient. They don't rot or warp and are extremely low-maintenance. https://www.diigo.com/user/mapescanopies in 13 various colours. A fantastic choice for industrial buildings is the 5500 Series aluminum roll-up home window awning, which has arms to keep the weather out as well as an open side. This awning permits natural sunshine to go into throughout the winter while keeping your indoor temperature levels comfortable throughout the summertime.

The benefits of light weight aluminum home window awnings are lots of. These awnings are very easy to install as well as be available in various shades to complement any type of residence decoration. Because they're made from light weight aluminum, they require marginal maintenance. Aluminum window awnings can be self-installed or worked with to be installed by a professional. Normally, they're installed over a home window or positioned simply listed below seamless gutter piping. They'll provide shade for the windows in any type of room in your home, while still remaining aesthetically appealing.

One more popular alternative is the folding awning. This sort of awning is generally known as a "park design," as it starts as three separate awnings as well as is after that collaborated making use of specific items that are custom-cut. These awnings can be constructed from several sorts of light weight aluminum, including Atlantic, Aurora, and Mitered. In general, the closed ends of the mitered awnings aid prevent the sun from glow.

Awning windows can be manually run with a crank. Both of these alternatives have an indoor display to stop insects from getting in and allow the wind to stream via. Other awning home windows have a limiter that allows the window to open within a particular range. Awning home windows operate like a vent; they enable amazing air to enter as well as warmth to get away. The best part of this home window type is that it is affordable.

When selecting visit this hyperlink awning for your home, consider the color and also style. You can choose from a solid color or a stripe pattern, as well as they will certainly match the light weight aluminum door cover. They will last for years, as the durable aluminum frame is durable as well as rust-free. Along with that, you can additionally select from fixed or roll-up models. Moreover, these awnings are created to minimize power prices and block UV rays.

Light weight aluminum window awnings are an exceptional addition to your home, including visual allure while shielding your household from too much sunshine. Other than providing shade, these home windows can additionally help reduce energy expenses by up to 20%. This allows your air conditioning system to have a break. The added advantages make aluminum awnings a terrific investment for any kind of residence. If you are seeking a practical house accent that will certainly last for several years, light weight aluminum home window awnings can aid you.

There are numerous advantages of mounting an aluminum home window awning. These awnings can protect your home from the sun's UV rays, which can harm your furnishings. They are also low-maintenance, calling for minimal maintenance. If you have any kind of problems regarding maintenance, you can call United Aluminum for a totally free estimate and installment. They will certainly give window awning installment in the Phoenix City area. You will certainly likewise be happily shocked at the difference that aluminum window awnings make.

When selecting aluminum home window awnings, you can locate them in a variety of colors as well as styles. In order to mount one, the awnings must be connected to the home window framework between the stringers. Once the awning has actually been attached, you can begin extending the awning from the top to the bottom. Make certain to safeguard it near the bottom. You can utilize screws to secure the awning to the home window structure. You may require to add added support braces over the window relying on its dimension.

In addition to being attractive and convenient, light weight aluminum home window awnings are also very resilient. They don't rot or warp and are extremely low-maintenance. https://www.diigo.com/user/mapescanopies in 13 various colours. A fantastic choice for industrial buildings is the 5500 Series aluminum roll-up home window awning, which has arms to keep the weather out as well as an open side. This awning permits natural sunshine to go into throughout the winter while keeping your indoor temperature levels comfortable throughout the summertime.

The benefits of light weight aluminum home window awnings are lots of. These awnings are very easy to install as well as be available in various shades to complement any type of residence decoration. Because they're made from light weight aluminum, they require marginal maintenance. Aluminum window awnings can be self-installed or worked with to be installed by a professional. Normally, they're installed over a home window or positioned simply listed below seamless gutter piping. They'll provide shade for the windows in any type of room in your home, while still remaining aesthetically appealing.

One more popular alternative is the folding awning. This sort of awning is generally known as a "park design," as it starts as three separate awnings as well as is after that collaborated making use of specific items that are custom-cut. These awnings can be constructed from several sorts of light weight aluminum, including Atlantic, Aurora, and Mitered. In general, the closed ends of the mitered awnings aid prevent the sun from glow.

Awning windows can be manually run with a crank. Both of these alternatives have an indoor display to stop insects from getting in and allow the wind to stream via. Other awning home windows have a limiter that allows the window to open within a particular range. Awning home windows operate like a vent; they enable amazing air to enter as well as warmth to get away. The best part of this home window type is that it is affordable.

When selecting visit this hyperlink awning for your home, consider the color and also style. You can choose from a solid color or a stripe pattern, as well as they will certainly match the light weight aluminum door cover. They will last for years, as the durable aluminum frame is durable as well as rust-free. Along with that, you can additionally select from fixed or roll-up models. Moreover, these awnings are created to minimize power prices and block UV rays.

Light weight aluminum window awnings are an exceptional addition to your home, including visual allure while shielding your household from too much sunshine. Other than providing shade, these home windows can additionally help reduce energy expenses by up to 20%. This allows your air conditioning system to have a break. The added advantages make aluminum awnings a terrific investment for any kind of residence. If you are seeking a practical house accent that will certainly last for several years, light weight aluminum home window awnings can aid you.

There are numerous advantages of mounting an aluminum home window awning. These awnings can protect your home from the sun's UV rays, which can harm your furnishings. They are also low-maintenance, calling for minimal maintenance. If you have any kind of problems regarding maintenance, you can call United Aluminum for a totally free estimate and installment. They will certainly give window awning installment in the Phoenix City area. You will certainly likewise be happily shocked at the difference that aluminum window awnings make.

SPOILER ALERT!

Listed Below Are Some Crucial Elements To Take Into Consideration Before Purchasing Aluminum Window Awnings

Article by-Ferguson Bilde

If you intend to protect your doors and windows, aluminum home window awnings are a fantastic option. They are lightweight as well as nearly maintenance-free and also be available in a variety of colors to match any type of style. You can choose between a selection of baked-on colors to complement your house. You can also choose a mix of shades to include much more allure. Below are some options to consider when searching for your following awning.

They can use you excellent benefits year-round, as well! In addition to protecting your residence from harmful UV rays, these awnings can aid maintain indoor temperatures down. They can additionally assist maintain the sun from fading your furniture as well as avoiding fading. Even during https://about.me/mapescanopies , they can safeguard your home windows from destructive freeze-thaw conditions. Water-tight aluminum window awnings can also secure your windows from freezing rainfall.

The aluminum home window awnings are created to match light weight aluminum door covers and also offer wonderful defense versus rain and also snow. They can be found in 13 different colors and also include a built-in front gutter. https://www.bizjournals.com/charlotte/news/2021/09/09/93m-home-sale-sets-record-in-canopy-mls.html can be stationary or roll-up and also include a five-year makers warranty. These canopies are durable as well as resistant to rust. These awnings are also constructed to reduce your energy costs, as they block the UV rays.

Aside from shielding people and vehicles from the sun, light weight aluminum awnings can add a makeover to your house. They can supply shade for your windows and also outdoor patio. You can pick the color that best enhances the shade of your roof covering and exterior siding. They can be connected to ceiling fans or skylights, too. And obviously, you can always choose to include a screen unit, too. These window awnings are likewise an excellent means to expand your space as well as delight in the outdoors.

If you intend to protect your doors and windows, aluminum home window awnings are a fantastic option. They are lightweight as well as nearly maintenance-free and also be available in a variety of colors to match any type of style. You can choose between a selection of baked-on colors to complement your house. You can also choose a mix of shades to include much more allure. Below are some options to consider when searching for your following awning.

They can use you excellent benefits year-round, as well! In addition to protecting your residence from harmful UV rays, these awnings can aid maintain indoor temperatures down. They can additionally assist maintain the sun from fading your furniture as well as avoiding fading. Even during https://about.me/mapescanopies , they can safeguard your home windows from destructive freeze-thaw conditions. Water-tight aluminum window awnings can also secure your windows from freezing rainfall.